CAD/ERP integration for efficient production planning

The increasing complexity of manufactured products is associated with many problems at the stage of the production preparation process. Before the machine, often consisting of hundreds or thousands of components, reaches the production departments, it must first be processed from the flat structure of the bill of materials from the CAD system to the so-called production BOM. This task can be very laborious.

Considering the time that the planner would spend manually transferring the structure to the system, the cost of starting production and the number of errors made may simply be high, which in turn translates into the price of the finished product. We have designed a tool that will collect and process the entire structure of the product, creating inventory and production BOMs, ready to be ordered for production, especially for companies that face the above problem every day.

Advantages of CAD Connector

Data consistency

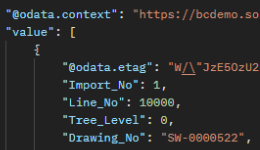

Thanks to the integration via modern REST API, the product structure is automatically sent to the ERP.

Time saving

The time needed to prepare a full product structure for material procurement and production can be reduced by up to 100%.

No errors

We have reduced the number of errors related to the manual introduction of the structure to the ERP system to zero.

Data validation

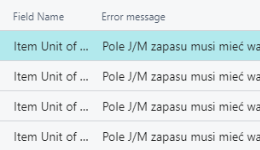

Already at the stage of sending the structure to the ERP, the correctness of the sent structure can be automatically validated, thanks to which the constructor can immediately obtain information about its correctness.

Error handling

Errors at the design stage will always appear. Our solution, as part of the advanced configuration of cases, is able to verify the correctness of the sent structure at the input.

Automation

You no longer need to create new inventory or picking BOMs and finally production BOMs in the ERP system manually. CAD Connector can create them automatically.

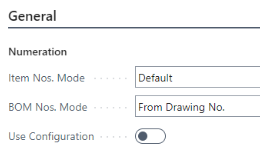

Parameterization

Each field in the import is configurable, thanks to which we can get full freedom in the business logic of data processing.

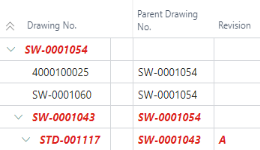

Versioning

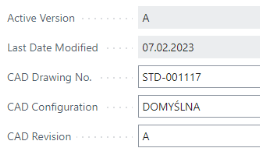

Each version modification or revision of the structure is entered into the ERP system as a new version, thanks to which the planner has access to the full design history of the product.

Selected program functions

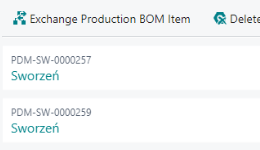

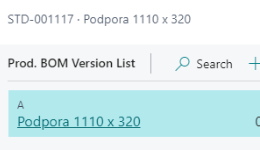

BOM

Access to the construction BOM structure (clear structure in the form of a tree)

Validation

Validation of data correctness and completeness.

Parameterization

...and automating the data completion process.

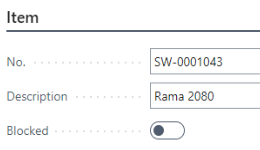

Stock indexes

Automatic creation of stock indexes for assemblies and details and/or production BOMs.

Central management

Management of all technological documentation (BOM and route) from one place.

Control

Documentation version control based on engineering BOM revisions

Up-to-date documentation

Update of technological documentation in case of structural changes

Integration

Full integration with the Microsoft Dynamics 365 Business Central environment.

CAD Connector packages

Find out more

Want to know more? Do you have any questions? Check out our FAQ

Is your company interested in cooperation?Contact us!

SOLIDEXPERT POLSKA SP. Z O.O.

ul. Gabrieli Zapolskiej 44, 30-126 Kraków

fax. 12 626 00 92, office@solidexpert.com

NIP 6772380230, REGON: 123060159, BDO: 000329881

-

Since 2002, we have established cooperation with 3,500 companies

and trained over 9,500 people -

We are winners of many industry awards

e.g. for the best customer service -

We have numerous certificates confirming our competences